Article: Control Tower SE Pillar Maintenance

Control Tower SE Pillar Maintenance

The number one question we get about the CT and SE Pillar is in regards to maintenance.

The straight forward answer is that no matter what you do with the SE Pillar, like all quartz, it will begin to devitrify over time. Over a long time frame no ones maintenance is as perfect as they think it is. That being said, if you want it to look nice for those melt shots for as long as possible here are some pieces of advice for keeping the SE Pillar and CT looking their best.

Tip #1: Do Not Use the Items at Elevated Temperatures

Doing so will scorch the pillar and possibly the CT itself. An ounce of prevention is worth a pound of cure. The less scorching the less material that will need flame polishing, the less long term devitrification.

Tip #2: Do Not Heat Up the SE Pillar in a Dirty Tower.

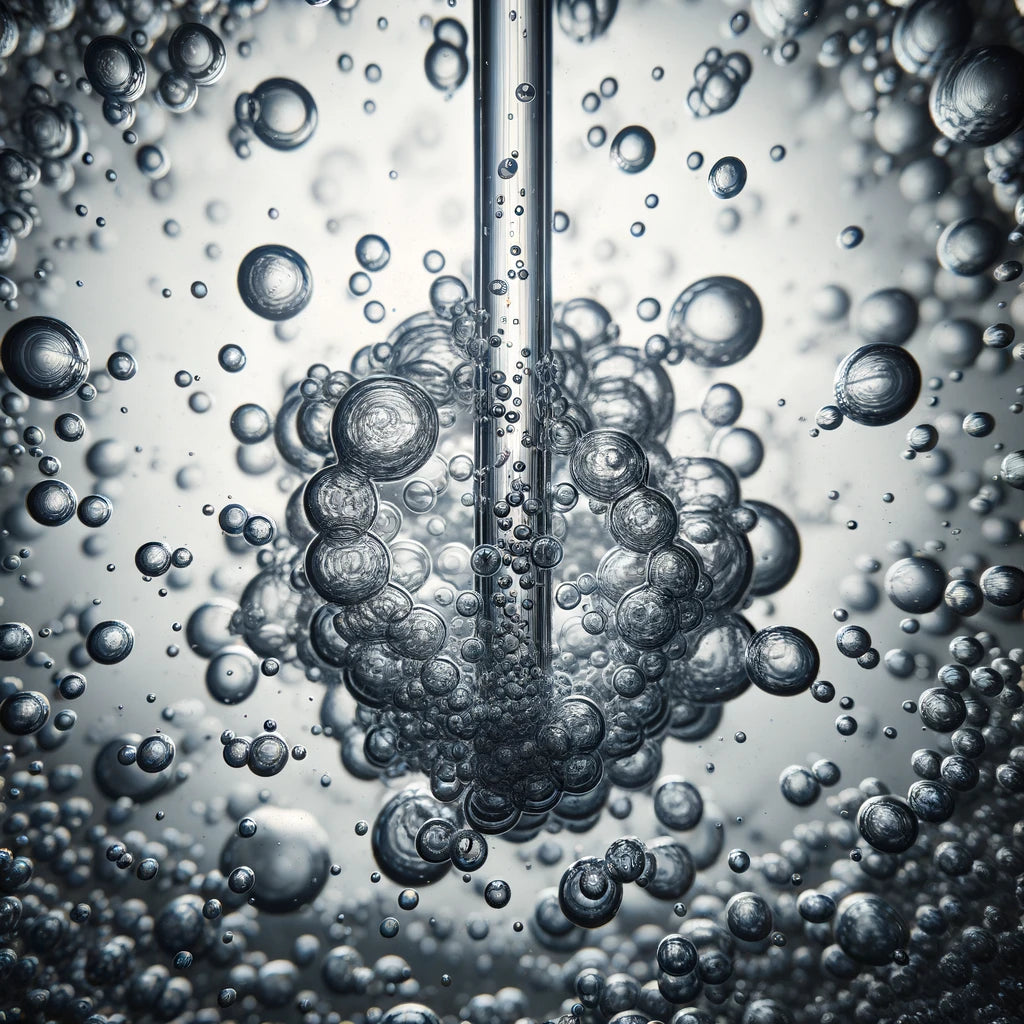

Nucleation sites work both ways. Nucleation is not just boiling. Nucleation is when a substance or mixture phase transitions from a liquid to gas, gas to liquid, or liquid to solid. The nucleation sites on the SE Pillar can work as condensation sites if it is being heated inside a CT with trace oil. As that trace oil turns into a vapor, it will favor condensing to the relatively colder SE Pillar. As the SE Pillar slowly heats up, the condensed oil begins to bake and char on the surface.

Tip #3: Make Sure Both Items Are Fully Clean Before Heating Them Up Together.

You can make sure that both items are fully clean by following these steps:

WARNING: Alcohol is a flammable solvent. Do not operate an open flame around alcohol. Do not have your iso baths anywhere near an open flame. Make sure all materials are dry before firing. Also exercise caution as to not incur any burns if/when handling hot quartz.

- After use: Remove SE Pillar from CT.

- Place both CT and SE Pillar in ISO soak separate. (Do not submerge hot. Warm is ok, hot is not.)

- Remove from soak and place in ISO rinse.

- Remove from ISO rinse and dry both with lint free cloth.

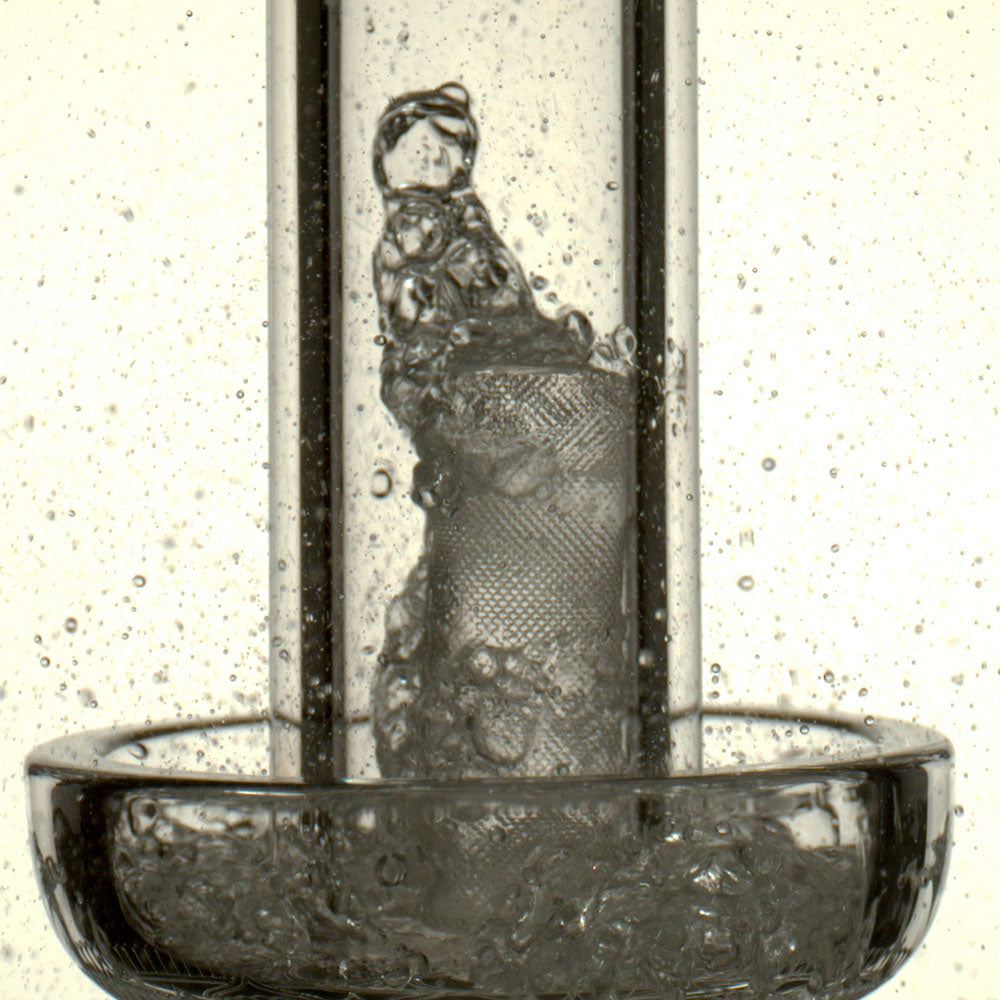

- Lightly flame polish the SE Pillar outside of the CT.

Exercise caution as to not burn yourself handling a hot SE Pillar. - Flame polish the CT until no vapor is rising from the CT.

- Replace pillar in CT

- The item is now ready for use.

Closing Maintenance Remarks:

It is well established that flame polishing quartz can cause devitrification if you are repeatedly burning those contaminants on the surface. The less contamination the surface has on it, the less likely it is to experience devitrification during a flame polish. A light flame polish to remove a light contamination should not have any immediate significant impact. However it can have a noticeable visual impact over time. The author has not noticed a significant change in function from a new pillar to a devitrified one and is of the opinion it only needs to be replaced when it is damaged or for aesthetic reasons solely.